|

Shipbuilding is the construction of ships. It normally takes place in a specialized facility known as a shipyard. Shipbuilders, also called shipwrights, follow a specialized occupation that traces its roots to before recorded history.

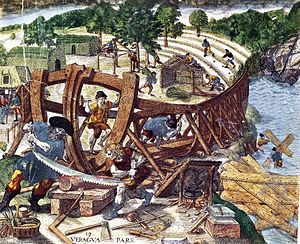

An expedition’s shipwrights building a brigantine, 1541. Modern shipbuilding makes considerable use of prefabricated sections. Entire multi-deck segments of the hull or superstructure will be built elsewhere in the yard, transported to the building dock or slipway, then lifted into place. This is known as "block construction". The most modern shipyards pre-install equipment, pipes, electrical cables, and any other components within the blocks, to minimize the effort needed to assemble or install components deep within the hull once it is welded together. This was first introduced by Alstom Chantiers de l’Atlantique when they built the largest Ocean Liner in the world Cunard’s RMS Queen Mary 2.

Ship breaking near Chittagong, Bangladesh breaking or ship demolition is a type of ship disposal involving the breaking up of ships for scrap recycling, with the hulls being discarded in ship graveyards. Most ships have a lifespan of a few decades before there is so much wear that refitting and repair becomes uneconomical. Ship breaking allows materials from the ship, especially steel, to be reused. Equipment on board the vessel can also be reused Until the late 20th century, ship breaking took place in port cities of industrialized countries such as the United Kingdom and the United States. Today, most ship breaking yards are in Alang in India, Chittagong in Bangladesh, Aliaga in Turkey and Gadani near Karachi in Pakistan, due to lower labor costs and less stringent environmental regulations dealing with the disposal of lead paint and other toxic substances. Some "breakers" still remain in the United States which work primarily on government surplus vessels. There are also some in Dubai, UAE for tankers. China used to be an important player in the 1990s. It is now trying to reposition itself in more environmentally friendly industries.

MS Oasis of the Seas, the world’s largest passenger ship, was built in Turku by South Korean-owned shipbuilding group STX Europe.

From Wikipedia, the free encyclopedia : Repair and maintenance of ships |